Carriage of Bulk Cargoes

Many of Skuld’s Members carry soybean bulk cargoes from North and South America to the Far East, in particular to China. Soybeans are a high value cargo, the price of which can fluctuate significantly. Claims arising from damaged cargoes can be very significant, with one recent matter resulting in a headline claim figure of several million USD. Taking good care of this cargo is therefore very important for effective loss prevention. Part of that loss prevention includes both fumigating the cargo and ventilating it.

Fumigation of soybean cargo may be required because of insect infestation found at loading, compliance with contractual specifications, or to issue a phytosanitary inspection certification. Voyage times between countries where soybeans are grown and countries where soybeans are in demand, can range from three to six weeks. Rather than undertaking a lengthy fumigation at the port of origin, soybeans are normally fumigated on passage. In recent months, it has become apparent that fumigators are requesting much longer fumigation times than has previously been the case.

What is a fumigant

Fumigants are pesticides, or mixtures of pesticides, that produce a gas that is toxic to most pests. Aluminium phosphide, the most common in-transit fumigant, is a solid that reacts with moisture in the air to liberate phosphine. The efficacy of using phosphine as a fumigant depends on the ambient temperature, its concentration and exposure time.

Methods of fumigant application

There are three main systems to fumigate bulk cargoes in transit, the first two of which are largely similar.

Surface Application and Trench-in Application

Aluminium phosphide is usually applied using belts, ropes, blankets, strips or sleeves, which are readily retrievable once fumigation is complete and leave little physical residue. In surface application, the metal phosphide packages are placed on top of the stow and the produced phosphine, which is slightly heavier than air, gradually permeates through the stow. Trench-in application is practically the same, the only difference being that the fumigant packages are buried approximately 30 cm beneath the surface of the stow. The advantages of using surface or trench-in methods are ease of application and lower costs. Surface and trench-in applications are commonly encountered on ships.

J-System/ Recirculation Application

The principal drawback of the first two methods is the slow phosphine permeation through the stow. This becomes a limiting factor in deep stows and using a recirculation system, can increase the rate of permeation and decrease the fumigation time. The fumigant packages are placed on the surface of the stow or trenched-in and, using electric fans and pipework, the phosphine is piped from the headspace to the tank top and released beneath the stow. This allows the phosphine to circulate through the stow and halves the minimum fumigation time.

Available Guidelines/ Regulations

With the exception of the instructions provided by the fumigant manufacturers and the US Department of Agriculture’s (USDA) Fumigation Handbook, there are few other guidelines dealing with in-transit fumigation. The International Maritime Solid Bulk Cargoes Code (IMSBC) provides recommendations on fumigation of cargo holds, including in-transit, but offers no specific details of fumigation periods or concentrations*.

Manufacturers’ Guidelines

Fumigant manufacturers provide details of the minimum application time, which is dependent on the ambient temperature. However, often these guidelines do not apply to bulk shipments as they assume the fumigant can be uniformly applied. The rate of phosphine gas generation slows in cooler conditions, leading to longer minimum fumigation periods.

Table 1 - A typical manufacturers’ fumigation time guidelines, assuming uniform application.

| Ambient Temperature | Fumigation Period |

|

5°C |

Do not fumigate |

|

5-12°C |

10 days (240 hours) |

|

12-15°C |

5 days (120 hours) |

|

16-20°C |

4 days (96 hours) |

|

> 20°C |

3 days (72 hours) |

USDA Handbook

The most comprehensive and specific guide on in-transit fumigation of soybeans is the USDA’s Fumigation Handbook**. This provides recommended minimum fumigant exposure times according to the depth of stow and the method of fumigation.

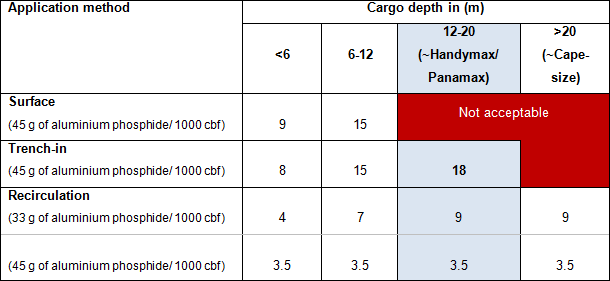

Table 2 - Minimum fumigation time by commodity depth (reproduced from USDA Fumigation Handbook), 18 days being a frequently specified application period for Handymax and Panamax size ships.

Other Guidelines

No official guidelines appear to exist for Brazil. Brazilian fumigators often stipulate in-transit fumigation periods of 10 days at aluminium phosphide concentrations of 28.5 grams per 1,000 cubic feet - significantly lower than the 45 grams per 1,000 cubic feet recommended by the USDA. It is not clear if these shorter periods or lower doses relate to different pest profiles or previous fumigation of the cargo whilst on shore.

Problems for Master of the Vessel

Fumigation requirements can pose problems for the Master, not just for safety reasons, but also because it may prevent him from ventilating the cargo during the voyage. If the Master does not ventilate the cargo he is open to criticism if the surface is degraded on arrival. Further, the Chinese courts in particular have previously found owners liable for cargo damages, which they believe are could have been prevented by ventilation, particularly when ventilation was not carried out or there was a failure to keep a proper ventilation record.

Recently, many US and South American fumigators have stipulated that holds must remain under fumigation for the duration of the voyage. Further, the USDA Handbook recommends that fumigated holds remain sealed throughout.

This places the Master in a dilemma with no easy immediate answer, as he seemingly has a choice between compromising the effectiveness of the fumigation or risk damage to the cargo by not ventilating (assuming weather conditions permit).

Even though ventilation - or damage caused by a lack of ventilation - may at times be confined to the top layer of a cargo, Port Customs & Inspections Departments have a tendency to focus in on vessels where there is significant surface deterioration on arrival as compared to vessels where the cargo - on visual inspection - appears to be free of significant defects. In particular as some surface damage may encourage a Receiver to make a claim or a more substantial claim than would otherwise be the case.

Advice

- On most Handymax and Panamax vessels, the fumigant is possibly of limited effect if only applied to the surface of the stow, and would be far more effective if “trenched-in”. For ships with holds deeper than 20 m, typically cape-size vessels, the use of a recirculation system needs to be considered.

- Using a recirculation system can reduce the fumigation period on typical Handymax and Panamax ships from 18 to 9 days or less.

- Paragraph 3.5 of the 2009 IMSBC Code, which was mandatory from January 2011, addresses (broadly) ventilation during the voyage with 3.6 briefly addressing fumigation - which is explored in greater detail in a supplement to the Code : MSC.1 Circ 1264. At Paragraph 3.3.2.1 of that supplement it is stated that in-transit fumigation should only be carried out at the discretion of the master. This again places a burden on the Master in making a decision, that should preferably be addressed ahead of time in the charterparty and contract of carriage (as embodied in the Bills of Lading).

- Keeping accurate records of when the cargo was under fumigation and when it was ventilated is very important. As is the record of any days when ventilation was not possible, either because fumigation has not been completed and / or conditions at sea do not permit ventilation to take place.

- If the planned fumigation time allows few or no chances to ventilate on the passage, the Owners should inform all interested parties prior to the voyage commencing. At least the Master may need to issue a protest in case ventilation had been envisaged for the cargo on the voyage at hand.

- Charterparty clauses should be used that specifically tackle the questions of fumigation and ventilation; and that if fumigation is to take place for a certain period of time - at the order of Charterers / Shippers or their Agents - then it should be agreed that ventilation may not take place during such time with the vessel not being responsible for possible damage to the cargo that may result.

- Mate’s Receipts and Bills of Lading should reflect and clearly state if a cargo may not be ventilated for a certain period of time due requirements for fumigation.

- At times there has been a temptation to reduce costs, by using less fumigant but for a longer period of time, according to advices received by the Association there is no readily available evidence to suggest that arbitrarily extending exposure times, to compensate for significantly lower fumigant dosages, is effective.

Scientific support and information provided by Nico Zurcher, Hannaford Forensic Services (Asia)

* IMO (2009) Recommendations on the safe use of pesticides in ships applicable to the fumigation of cargo holds MSC.1/Circ.1264 Appendix 1, 3.1

** USDA (2006) Fumigation Handbook. Washington DC. Cap 2 ‘In-transit Fumigation - Vessels’ was revised in 2009.