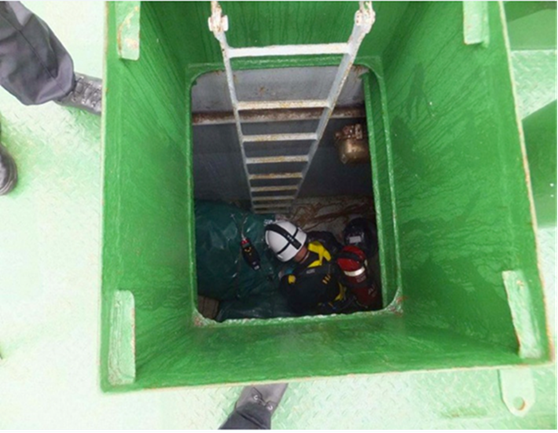

Enclosed space entry

Recently the Association noted a crew fatality incident caused by entering an enclosed zinc concentrate cargo hold. A chief officer of a bulk carrier was found lying unconscious in the cargo hold after he entered the hold alone without ventilation and tragically lost his life. It was later established that the cause of death was asphyxiation. Measurements performed the day after the accident showed that the level of oxygen in the air at the stairwell was 2.6%.

Lessons learned

Due to the cargo's nature of oxidation, ventilation and atmosphere tests are vital before entering holds and breathing apparatus is needed. At sea-level, humans require air that contains minimum 19.5% oxygen. Below that an environment will be unsafe for human life. Where oxygen in an enclosed space was consumed by oxidation the oxygen quantity will be replaced by carbon monoxide and when this happen a person may fall unconscious within a few breaths, and death may follow within three minutes.

Regulatory compliance

(i) It is stressed that the procedure in the company SMS for entry into enclosed space shall be strictly complied with, and the master should ensure that all crew members are well trained and fully familiar with the procedures. This Association has published an article to discuss the mandatory drill for entering into an enclosed space.

(ii) SOLAS Regulation III/19 requires mandatory enclosed space entry drills as well as rescue drills to be conducted every two months. All crew members who have responsibilities for entry in to enclosed spaces, or rescue therefrom, will have to participate in these drills.

Crews are to remember:

a. Always read and plan for all risks that are highlighted in the MSDS documentation

b. Always ventilate and test hazardous gases and oxygen content before entering enclosed space

c. Always have companions when entering enclosed space. Supervisor(s) to be present at the entrance and keep continuous communication with the entering crew.

(iii) Guidance for enclosed space entry from IMO Resolution A.1050(27) is attached to this article.

(iv) Section 3 of the IMSBC Code states that when transporting solid bulk cargoes, the crew must always be aware that such cargoes can be susceptible to oxidation.

Other precautions

We hereby repeat the precautions for concentrate transportation:

(i) The two main hazards to look out for when transporting mineral concentrates are that they may liquefy if shipped at moisture content in excess of their transportable moisture limit (TML) and present self-heating properties through oxidation especially if carried in bulk. Therefore, ventilate and test atmosphere before entering holds. Use breathing apparatus. See also Section 7 (Cargoes which may liquefy) of the IMSBC Code for further guidance. Otherwise, these cargoes are known to be non-combustible or have low fire risks.

(ii) Clean and dry bilge wells. Cover as appropriate to prevent cargo ingress. Test bilge system of cargo space to which cargo is to be loaded to ensure that it is in working order.

(iii) Take note that if there is heavy rain during loading or storage or even leakage into holds during carriage, the normal moisture content of the cargo could seriously increase. Under such circumstances, the vibration of the vessel may cause moisture to saturate, turning the concentrate into a slurry which could lead to a serious listing of the vessel.

(iv) Ventilate and test atmosphere before entry into cargo holds.

(v) Cases have also shown extensive damage e.g., discolouration, sweat and taint caused to cereal or coffee cargoes stowed in the same compartment due to the self-heating of cargo. Do not stow with other cargoes. Also avoid stowing with other types of ores to avoid cross contamination.

Members are advised to warn masters to pay particular attention to the transportation of zinc concentrate and the safety requirements for entry into enclosed spaces.