Liquefied natural gas (LNG) is stored and carried in an LNG/C’s (LNG Carrier) tanks at approximately -160°C. Additionally, there are LNG storage vessels called FSU (Floating Storage Units) and LNG vessels equipped with regasification plants - FSRUs(Floating Storage and Regasification Units). These vessels are stationary at various locations around the world. FSRUs are designed to store and convert the liquid back into natural gas state (NG) and send it to shore to be utilised for heating and/or power generation.

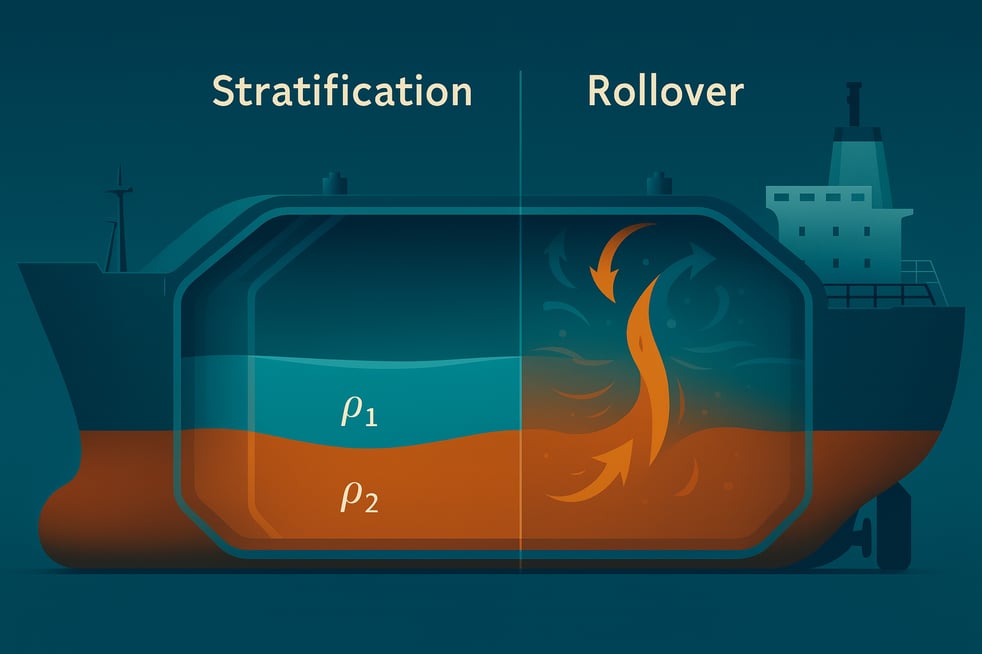

Two different batches of LNG with different compositions and densities may end up in the same tank. If they don’t mix properly, the liquid gas can settle in two layers, and this is called “stratification”.

The term “Rollover” describes a rapid mixing of the layers of LNG inside the tank, leading to a sudden uncontrollable increase in the boil-off gas (BoG). With an increased boil-off, the cargo tank pressure will rapidly increase, resulting in a potential venting of flammable gas to the atmosphere via the vent mast, opening of the cargo tank safety relief valves or in the worst case, structural damage.

Note: once the cargo tank safety relief valve has been opened, there is a risk of seal damage, which may result in the valve being unable to close fully, subsequently leading to potential loss of cargo and delays.

Stratification commonly occurs when lighter LNG is loaded above heavier LNG, or conversely, when heavier LNG is introduced beneath a lighter layer.

General Guidelines / Risk Assessment for Mixing of Cargo:

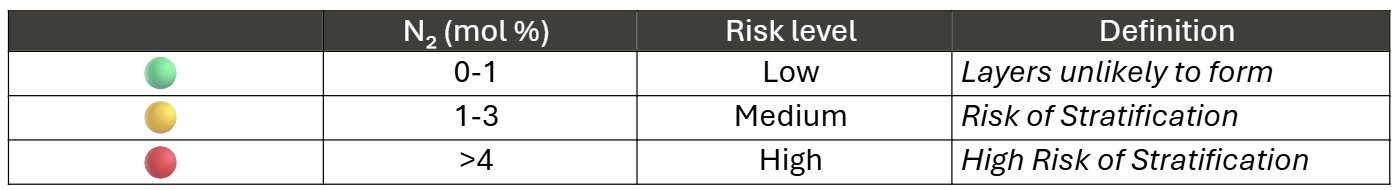

Nitrogen Content of Incoming Cargo:

There are indicators that can provide early signs of stratification: density profile, temperature profile and reduced boil-off rate. The boil-off rate will actually be reduced before the rollover event, which will rapidly cause a spike of the boil-off.

Stratification & Rollover Prevention:

The most effective stratification and rollover prevention is to avoid mixing LNG and loading into empty cargo tanks. SIGTTO Guidelines define an empty cargo tank as less than 800 m3 of LNG. However, this may vary depending on the type and size of the vessel. In order to acquire the exact figures, the manufacturer of the cargo tank should be consulted.

- It is important to properly plan and manage LNG loading operations. The certificate of quality shall be requested prior to loading, and the density compared to the LNG (heel) already onboard. This provides additional time for potential internal cargo transfer or other means to prevent stratification. Ageing and weathering of the cargo is a gradual change in LNG composition over time due to lighter components evaporating (boiling-off), making the remaining liquid richer in heavier components and this should be taken into consideration.

- Usually, the vessels are equipped with top filling systems on one or several tanks. If the incoming LNG is heavier, the top filling should be utilised to mix the cargo properly. Note, there are potential liquid level restrictions with respect to utilising top-filling. Additionally, top filling increases boil-off gas generation and can limit the feasible loading rate, depending on BOG handling capacity.

- General Loading Guideline:

-

If the incoming cargo is heavier (denser) than the one already onboard, use top filling.

-

If the incoming cargo is lighter (less dense) than the one already onboard, use bottom filling.

-

Aim for the highest safe loading rate – faster flow promotes mixing and reduces the risk of stratification.

-

Regasification Sendout Rate (FSRU Specific) - the rate at which the liquid cargo is regasified and sent ashore will affect the mixing in the cargo tank. With a higher sendout rate, there is less time for LNG to form layers and eventually rollover.

This circular provides general guidance. Actual risk and controls depend on ship and project-specific factors and must be confirmed against the vessel’s SMS and technical limits, such as tank layout, BoG handling capacity and sendout profiles.

Should you have any further questions or inquiries, please do not hesitate to contact the Skuld Loss Prevention Department.