The Club would like to draw its Members' attention to the continued dangers of fires which originate in the machinery space. Specifically, where the cause of the fire is as a result of a flammable liquid spraying onto a hot surface.

Typical root causes for such incidents have been identified as:

- Missing pipe brackets/supports on oil systems leading to increased vibrations and subsequent cracks or even breakage of the oil piping system.

- Missing cup over the fuel injector valve.

- Original insulation or screening of hot surfaces was not maintained correctly.

- Original insulation or screening of hot surfaces was not sufficient for preventing oil spray onto hot surfaces.

- Insulation soaked with oil caught fire when sufficiently heated up.

- Oil leakages from engine components like exhaust valve indicators spraying onto the exhaust manifold.

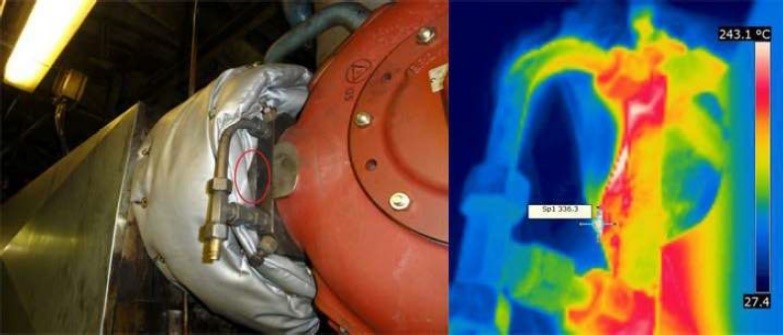

It is recommended to enhance prevention and protection against such fires and that a proactive inspection and evaluation programme is incorporated as part of the ongoing planned maintenance schedule to ensure all piping systems and equipment is maintained corrected and that design is appropriate. Combined into this the use of a thermal imaging camera can have great benefits of identifying any areas where a hot spot is developing or has not been identified before.

Routines for this screening should include but not be limited to:

- Mechanical inspection and maintenance of all the internal oil piping on machinery including external oil piping near to all equipment that can potentially leak onto hot surfaces.

- Inspection and maintenance of all the original screening arrangements and insulation installed on equipment.

- Inspection and maintenance of screening and insulation of external oil piping near to the machinery that can potentially leak onto hot surfaces.

- Inspection and evaluation of actual piping design and screening/insulation design.

A screening template can be made for all equipment in the engine room identified as part of this process, and these completed templates will help record the lifecycle of the screening/insulation and give early indication of deterioration or damage in order to determine when replacement will be needed to maintain the original standard.

As guidance equipment which may need to be incorporated into the screening could include but not be limited to:

- Main engines

- Auxiliary engines

- Emergency generators

- Oil fired boilers and incinerators

- Waste heat recovery units